Standards and their classification

A

standard is a physical representation of a unit of measurement. It is a piece

of equipment having a known measure of physical quantity. They are used for the

measurements of other physical quantities by comparison methods.

Standards of measurements can be

classified in to;

i.

International standards

ii.

Primary standards

iii.

Secondary standards

iv.

Working standards

Visit EEE Made Easy

- International

standards

These are defined on the basis of

international agreement. They represent the units of measurements which are

closest to the possible accuracy attainable with present day technological and

scientific methods. International standards are checked and evaluated regularly

against absolute measurements in terms of the fundamental units. These

standards are maintained at the International Bureau of Weights and

Measures and are not available to the ordinary user of measuring

instruments for the purposes of calibration or comparison.

The international unit of length was

defined in 1960 in terms of the wavelength of Krypton-86. The metre is

equal to 1,650,763.73 wavelengths in vaccum of the orange-red light radiation

of the Krypton-86 atom in its transition between levels 2 p10 and 5d5.

In 1983, the metre was redefined.

The metre is now, the length travelled by light in vaccum in a time interval of

1/299792458 sec.

- Primary

standards (Absolute standards)

The Primary standards are the absolute standards

which can be used as the ultimate reference standards. These standards are

maintained by National Standards Laboratories in different parts

of the world. The primary standards which represent the fundamental units are

independently calibrated by absolute measurements at each of the national

laboratories. One of the main functions of the primary standards is the

verifications and calibration of secondary standards.

The primary standards are very few in number. These

standards have the highest possible accuracy and stability.

The primary unit of mass is a prototype kilogramme

kept at National Physical Laboratories of every country. This has

an accuracy of 1 part in 108.

- Secondary

standards

The secondary standards are the basic

reference standards used in industrial measurement laboratories. They are sent

periodically to the national standards laboratories for calibration and

comparison against primary standards. The secondary standards are sent back to

the industry by the National laboratories with a certification regarding their

measured values in terms of primary standards.

The secondary standards of mass are

kept by industrial laboratories. These standards have an accuracy of 1 ppm and

are checked against the primary standards.

- Working

standards

These

standards are used to check and calibrate general laboratory instrument for

their accuracy and performance.

The

working standards of mass and length are available in a wide range of values so

that, they suit any kind of application. The working standards of mass have an

accuracy of 5 ppm and are checked against the secondary standards. The working

standards of length are usually precision gauge blocks made up of steel. These

blocks have two parallel surfaces and the distance between the two surfaces is

specified. They have an accuracy of 1 ppm.

Classification of Instruments

Instruments can be broadly

classified in to

- Absolute

instruments

- Secondary

instruments

Absolute instruments give

the magnitude of the quantity under measurement in terms of physical constants

of the instruments.

e.g:- Tangent galvanometer, Rayleigh’s current

balance.

In secondary instruments, the quantity

under measurement can only be measured by observing the output of the

instrument. The secondary instruments should be calibrated by comparing with an

absolute instrument or another secondary instrument which has already been

calibrated against an absolute instrument.

e.g:- Voltmeter, pressure gauge.

The secondary instruments are the commonly used instruments compared to the absolute

instruments.

Electrical measuring instruments may be classified according

to their functions as;

(i)

Indicating instruments

(ii)Integrating instruments (iii) Recording instruments

- Indicating

instruments:-

These

instruments directly indicate the value of the electrical quantity at the time

when it is being measured. In these instruments, a pointer moving over a

graduated scale directly gives the value of the electrical quantity being

measured.

e.g:-

Ammeter, voltmeter, wattmeter.

- Integrating

instruments

The

instruments which measure the total quantity of electricity (in Ampere hours )

or electrical energy (in Watt hours) in a given time are called integrating

instruments. In such instruments, there are a set of dials and pointers which

register the total quantity of electricity or electrical energy supplied to the

load.

e.g:- Ampere- Hour meter, Watt-hour meter.

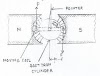

- Recording

instruments

Recording instruments give a continuous record of

the variations of the electrical quantity to be measured. A recording

instrument is merely an indicating instrument with a pen attached to its

pointer. The pen rests lightly on a chart wrapped over a drum moving with a

slow uniform speed. The motion of the drum is in a direction perpendicular to

the direction of the pointer. The path traced out by the pen indicates the

manner in which the quantity being measured, has varied during the time of the

record.

e.g:- Recording voltmeters, Recording ammeters in

supply stations.

………………………………………………………………………………………………….. Reference:-

(i)

A.K Sawhney, Electrical and Electronic Instrumentation

and Measurements, page no:- 181-182]

……………………………………………………………………………………………………………

Standards and their classification

![Standards and their classification]() Reviewed by Sikha

on

December 29, 2012

Rating:

Reviewed by Sikha

on

December 29, 2012

Rating:

No comments:

Post a Comment