Share and earn!!

It is the idealized cycle for steam power

plants. This cycle is shown on p-v,T-v, h-s, diagram It consists of following processes:

Process

1-2: Water from the condenser at low pressure

is pumped into the boiler at

high pressure.

This process is reversible adiabatic.

Process

2-3: Water is converted into steam at

constant pressure by the addition of heat

in the boiler.

Process

3-4: Reversible adiabatic expansion of steam

in the steam turbine.

Process

4-1: Constant pressure heat rejection in the

condenser to convert condensate

in to water.

Ideal Rankine cycle

In an

ideal Rankine cycle the pump and turbine would be isentropic, i.e., the pump

and turbine would generate no entropy and hence maximize the net work output. Processes 1-2 and 3-4 would be represented by

vertical lines on the T-S diagram and more closely resemble that of the Carnot

cycle. The Rankine cycle shown here prevents the vapour ending up in the superheat region

after the expansion in the turbine, which reduces the energy removed by the

condensers.

The p-v diagram, h-s diagram and T-s

diagram are given below.

The efficiency

of ideal Rankine cycle is not achieved, which is a reference value of an ideal

steam power plant.

In a real power

plant cycle (the name 'Rankine' cycle used only for the ideal cycle), the

compression by the pump and the expansion in the turbine are not isentropic. In

other words, these processes are non-reversible and entropy is increased during

the two processes. This somewhat increases the power required by the pump and

decreases the power generated by the turbine. In particular the efficiency of

the steam turbine will be limited by water droplet formation. As the water condenses,

water droplets hit the turbine blades at high speed causing pitting and

erosion, gradually decreasing the life of turbine blades and efficiency of the

turbine. The easiest way to overcome this problem is by superheating the steam.

On the T-s diagram above, state 3 is above a two phase region of steam and

water so after expansion the steam will be very wet. By superheating, state 3

will move to the right of the diagram and hence produce a drier steam after

expansion.

Due to

the pressure drops in the passages and the irreversibilities in various

components, the ideal Rankine cycle deviates from the actual Rankine cycle.

The above fig

shows the actual Rankine cycle where, 1-21 is due to the

irreversible process in feed pump and 3-41 is due to the turbine

irreversibility.

The actual efficiency of steam power plant,

by replacing the enthalpies h2 and h4 by h21

and h41 will be,

The actual thermal efficiency, should be made as

close as possible to ideal thermal efficiency.

The thermal

efficiency of a steam power plant can be increased by following ways;

a) Increase

in initial steam pressure.

b) Increase

in initial steam temperature.

c) Increase

in condenser vaccum.

d) Regenerative

feed water heating.

e) By

reheating.

f) By

use of economizer.

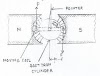

Reheat cycle (Rankine cycle with reheat):-

Reheating is

a process by which steam at the end of expansion in turbine stages is taken out

to boiler or reheater for resuperheating. This reheated steam does more work in

the next stage of turbine and increases the thermal efficiency of the plant.

The fig. Given below shows a Rankine cycle with single reheat without any feed

water heating.

The

purpose of a reheating cycle is to remove the moisture carried by the steam at

the final stages of the expansion process. In this variation, two turbines work

in series. The first accepts vapour from the boiler at high pressure. After the

vapour has passed through the first

turbine, it re-enters the boiler and is reheated

before passing through a second, lower-pressure, turbine. The reheat

temperatures are very close or equal to the inlet temperatures, whereas the

optimum reheat pressure needed is only one fourth of the original boiler

pressure. Among other advantages, this prevents the vapour from condensing

during its expansion and thereby damaging the turbine blades, and improves the

efficiency of the cycle, given that more of the heat flow into the cycle occurs

at higher temperature.[ The reheat cycle was first introduced in the 1920s,but

was not operational for long due to technical difficulties. In the [1940s] it

was reintroduced with the increasing manufacture of high-pressure boilers, and

eventually double reheating was introduced in the 1950s. The idea behind double

reheating is to increase the average temperature. It was observed that more

than two stages of reheating are unnecessary, since the next stage increases

the cycle efficiency only half as much as the preceding stage. Today, double

reheating is commonly used in power plants that operate under supercritical

pressure].

The constant

pressure line 5-6 shows the reheat process. If QR is the heat

supplied during the reheating, the total heat supplied will be

Therefore, the thermal efficiency of plant with

reheat will be given by,

The efficiency of the cycle depends upon the

reheat pressure. There is an optimum value of reheat pressure. At first reheat,

it is 0.2 to 0.25 times the initial pressure of steam whereas for next reheat,

it is 0.2 to 0.25 times the first reheat pressure of steam and so on.

Regenerative

cycle:-

The heating of feed water by steam extracted

at various points while sending it to the boiler is termed as regenerative

heating. Thermal efficiency can be increased by 10% and therefore it is

universally used in all steam power plants. The large no. of heaters makes the

system design more complicated and leads to considerable loss of pressure. The

no. of heaters employed in large steam plants is 6 to 10 with a final feed

water temperature of about 2850C.

Heat rate:-

It is a measure of the performance of the

power plant in converting heat to useful output. It is defined as the no. of

heat units required to develop unit power output in an hour. The heat rate

decreases with the increase in thermal efficiency.

Rankine cycle

Reviewed by Sikha

on

July 03, 2013

Rating:

Reviewed by Sikha

on

July 03, 2013

Rating:

Reviewed by Sikha

on

July 03, 2013

Rating:

Reviewed by Sikha

on

July 03, 2013

Rating:

No comments:

Post a Comment