An

electrical machine is an electromechanical energy conversion device. The device

which converts electrical energy in to mechanical energy is called a motor. The

device which converts mechanical energy in to electrical energy is called a

generator.

Classification

of electrical machines

D.C generator

D.C

generator is a machine which converts mechanical energy in to electrical

energy. Direct –current generators are used to supply power for radio equipment, for battery

charging

for

electrolytic cells etc. a disadvantage common to all d.c machines is the

complexity of design, mainly due to the usage of brushgear. This brush gear can

also cause sparking.

A d.c machine consists essentially a

stationary part, called the field structure and a rotating part called, the

armature.

Principle of operation:

D.C generator is based on the

principle that whenever magnetic flux is cut by a moving conductor, an e.m.f is

induced in the conductor as per Faraday’s laws of electromagnetic induction.

The e.m.f so induced is an alternating e.m.f. it is made unidirectional with

the help of commutator and brushes. This e.m.f causes the flow of current in the

external circuit if the circuit is closed.

The direction of induced e.m.f is

given by Fleming’s right hand rule. Stretch out the right hand with first

finger, middle finger and thumb mutually perpendicular to each other. If the

first finger points in the direction of flux, and thumb in the direction of

motion of the conductor, then the middle finger will point in the direction of

the induced e.m.f..

Constructional details:-

The main parts of a d.c machine (a

generator or a motor) are described below.

1)

Yoke:-

It is the outermost cylindrical part of

the machine. The yoke is made of cast iron or cast steel or forged steel. The

yoke acts as the supporting frame for the machine and also completes the path

of the main magnetic flux. In small d.c machines, yoke is made up of cast iron.

In large d.c generators, the yoke is made of cast steel from the consideration

of better magnetic properties.

2)

Poles:-

The

pole consists of pole core and pole shoe. The field coil is wound on the pole

core. The poles are made of cast steel or forged steel. In some machines, poles

are made from laminated sheet steel. The main functios of the pole shoe are (a)

it supports the field coil. (b) it spreads out the magnetic flux in the air

gap. (since pole shoe is of large cross section, it reduces the reluctance of

the magnetic path.

3)

Field

coils:-

The

field coils are wound on pole cores. They are connected in series and the

connections are arranged so that due to the flow of current in these coils

alternate N and S poles are made. The field coils are made from enameled copper

wire.

4)

Armature:-

The

armature is that part of the d.c machine where an e.m.f is induced as it

rotates relative to the main field. The armature consists of the toothed core,

a winding dropped in the core slots, and a commutator mouted on the armature

shaft. The armature core is composed of silicon- steel laminations. The

armature winding consists of sections or coils.

5)

Commutator:-

The commutator, which is a typical component of d.c

machines, is a hollow cylinder. The commutator is made up of wedge shaped

segments of hogh conductivity hard drawn or copper forged copper. The segments

are insulated from each other by thin layer of mica. The function of the

commutator is to convert the e.m.f induced in the armature conductors in to

unidirectional voltage across the load impedance.

6)

Brushes:-

The

function of the brush is to collect current from the rotating commutator and

deliver it to the external load impedance. The brushes are made of carbon. The

brushes are mounted in a box type of brush holder and are held on the

commutator by a spring.

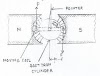

Simple d.c generator

The fig. gives the basic structure. When a coil is

rotated in a uniform magnetic field, an alternating emf is generated across the

terminals 1 and 2 of the coil. If a unidirectional current is desired in the

external circuit, the two ends of the coil ABCD are connected to the two

segments C1 and C2 which are insulated from each other.

When C1 is positive, the brush B1 makes contact with it.

But for the other half rotation, of the coil, the segment C2 becomes

positive and now this makes contact with the brush B2. Thus, we see

that the brush remains positive all the time, and hence a unidirectional

current results in the external circuit as shown below.

The current in the external circuit is

unidirectional. But its strength varies considerably. It raises and falls

between zero and maximum for each half rotation of the coil. This defect of

having large variations in the unidirectional e.m.f (or current) can be

overcome by having more coils on the rotor.

Types of D.C

generator:-

D.C

generators are generally classified according to the method used for field

excitation. Thus, they can be classified as

1. Separately

excited generator

2. Self

excited generator

D.C Machines

Reviewed by Sikha

on

July 03, 2013

Rating:

Reviewed by Sikha

on

July 03, 2013

Rating:

Reviewed by Sikha

on

July 03, 2013

Rating:

Reviewed by Sikha

on

July 03, 2013

Rating:

No comments:

Post a Comment