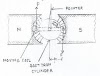

General layout of Steam Power Station|Steam Power plant

General layout of Steam Power Station

Units of Steam Power plant

The main power plant

can be subdivided into several smaller units namely,

(1). Fuel handling

unit.

(2). Ash handling unit.

(3). Boiler unit.

(4). Feedwater unit.

(5). Cooling water

unit.

(6). Generator unit.

Main flow circuits:-

The flow circuit can be

divided into four main circuits.

a) Fuel & Ash

circuit.

b) Air & Gas

circuit.

c) Feedwater &

Steam circuit.

d) Cooling water

circuit.

a) Fuel & Ash

circuit.

Steam can be generated from coal, gas, or

oil as the main fuel.

Fuel is stored in the storage and fed to the boiler through a conveyor belt.

From the storage plant, coal is delivered to the coal handling plant where it is pulverized ( i.e, crushed into small pieces), so that complete burning is possible and total energy can be extracted in terms of heat. It is required to control heat energy.

Therefore the coal is passed through the crushers, sizers, dryers and magnetic separator before feeding in to the boiler.

Fuel is stored in the storage and fed to the boiler through a conveyor belt.

From the storage plant, coal is delivered to the coal handling plant where it is pulverized ( i.e, crushed into small pieces), so that complete burning is possible and total energy can be extracted in terms of heat. It is required to control heat energy.

Therefore the coal is passed through the crushers, sizers, dryers and magnetic separator before feeding in to the boiler.

The coal is burnt in the boiler and the as

produced after the combustion of coal is removed to the ash handling plant and

then delivered to the ash storage plant for disposal.

The removal of ash from the boiler furnace is necessary for the proper burning of the coal.

The removal of ash from the boiler furnace is necessary for the proper burning of the coal.

During the light-up of the boiler, it is not

possible to burn the coal and therefore liquid fuels are required.

It is also required during the disturbance in boiler because it is easy to control the energy from liquid fuels.

It is also required during the disturbance in boiler because it is easy to control the energy from liquid fuels.

b) Air & Gas circuit.

Air is required for the complete

combustion of the fuel which is supplied through the forced draught (FD) fans

and induced draught (ID) fans.

In all large thermal power plants, both fans are used and normally they are in pairs to balance the boiler.

The air, which is fed to the boiler, is passed through the air preheater to extract some energy of flue gases coming out from the boiler after burning the coal.

It also helps in the proper burning of the coal.

The flue gases consist of gases and ash, which are passed through the precipitator (or dust collector) and then finally go to the atmosphere through the chimney.

In all large thermal power plants, both fans are used and normally they are in pairs to balance the boiler.

The air, which is fed to the boiler, is passed through the air preheater to extract some energy of flue gases coming out from the boiler after burning the coal.

It also helps in the proper burning of the coal.

The flue gases consist of gases and ash, which are passed through the precipitator (or dust collector) and then finally go to the atmosphere through the chimney.

c) Feedwater & Steam circuit.

If the seam power plant is of condensing

type, the steam is converted to water by the condenser.

Due to the safety of the turbine, the water used is demineralized (DM) and therefore it is not wasted (to have an economic operation of the plant).

Some part of steam and water is lost while passing through the different components of the system due to leakages.

This can be compensated by adding the makeup water in the feedwater system.

The boiler feed pump (BFP) feeds the water into the boiler drum where it is heated to form the steam.

The wet steam from the drum is again heated in the superheater, before it is passed to the turbine.

The superheated steam is expanded in the turbine to run it.

Due to the safety of the turbine, the water used is demineralized (DM) and therefore it is not wasted (to have an economic operation of the plant).

Some part of steam and water is lost while passing through the different components of the system due to leakages.

This can be compensated by adding the makeup water in the feedwater system.

The boiler feed pump (BFP) feeds the water into the boiler drum where it is heated to form the steam.

The wet steam from the drum is again heated in the superheater, before it is passed to the turbine.

The superheated steam is expanded in the turbine to run it.

Depending upon the size of the power plant

unit, where there are different stages of the prime mover.

High pressure (HP) turbine.

Intermediate pressure (IP) turbine.

Low pressure (LP) turbine.

The steam after the expansion in the HP turbine

is sent back to the boiler for reheating to increase the temperature and pressure.

After coming out from the LP turbine, steam is passed through the condenser in the hot well and finally to the boiler through the BFP.

After coming out from the LP turbine, steam is passed through the condenser in the hot well and finally to the boiler through the BFP.

a) Cooling water circuit.

To condensate the steam in condenser and maintaining low pressure in it,

a large quantity of cooling water is required, which is taken from the river or

pond.

After passing it through the condenser, it is fed back to the river or pond. When there is no enough water, the cooling tower or cooling ponds are used.

After passing it through the condenser, it is fed back to the river or pond. When there is no enough water, the cooling tower or cooling ponds are used.

Main parts of Steam Power Plant

(1). Boiler:-

Ø

2nd tallest part after the

chimney in a power plant.

Ø Used for producing the steam and reheating

the steam.

Ø

Two types: water-tube boilers & fire tube boilers

Water-tube boilers

· Generally

used.

· Water flows in the tube and fire is outside.

· Low stresses from pressure and temperature

differential and small drum size.

· Less weight of metal for a given size.

· Less liable to explode.

· Produce high pressure and quickly controlled

steam.

Fire-tube boilers

· Fire flows in the tube and water is outside.

· Cheap, but are more likely to explode.

· Outer shell of the fire tube boiler is more

than that of the water tube.

Since steam at

different pressure and temperature contain varying amounts of energy, the no.

of Kg steam generated is not an exact measure of the energy produced. The

capacity of a steam boiler is expressed as the total heat transferred by the

heating surface in BTU per hour.

The heat transfer process that occurs in a a steam generator is a steady flow process for which transferred heat is equal to the change in enthalpy of the fluid.

The boiler output, as measured by the heat absorbed by water and system is given by,

The heat transfer process that occurs in a a steam generator is a steady flow process for which transferred heat is equal to the change in enthalpy of the fluid.

The boiler output, as measured by the heat absorbed by water and system is given by,

ms→ weight of steam delivered by boiler, Kg/Hr

hs→

Enthalpy of steam at observed pressure and quality of temperature, BTU/Kg

hf→

Enthalpy of the fluid of feed water at observed condition, as water reaches the

boiler, BTU/Kg.

The overall boiler efficiency of a

steam generating unit at any operating condition is the ratio of the

transferred heat to the energy supplied by the fuel. ie, output divided by

input.

mf

→ Total weight of fuel fired per hour.(Kg)

F

→ High heat value of fuel as fired (BTU/Kg)

(2). Coal Mills:-

The

coal mills are used for drying of coal, grinding, and separation of particles

of the desired size, forming proper air-fuel ratio and suitable control of all

these operations.

The two systems of preparing and burning pulverized fuels are (a) the central or storage system where one independent plant prepares and transports to all units and (b) the unit or direct fire system in which one or more units connected to it.

Preheated forced air passed through pulverizer eliminates the necessity of separate driers.

The fuel is first crushed to a general size(1 cm) and then passed over the magnetic separator to remove the tramp iron such as nuts, bolts and rivets.

This crushed coal goes to the pulverizers and then directly to furnace.

The two systems of preparing and burning pulverized fuels are (a) the central or storage system where one independent plant prepares and transports to all units and (b) the unit or direct fire system in which one or more units connected to it.

Preheated forced air passed through pulverizer eliminates the necessity of separate driers.

The fuel is first crushed to a general size(1 cm) and then passed over the magnetic separator to remove the tramp iron such as nuts, bolts and rivets.

This crushed coal goes to the pulverizers and then directly to furnace.

Pulverizers may be divided in to four types

based on the method of fuel size reduction, namely

· Ball race

· Bowl mill

· Impact mill

· Ball mill

The advantages of pulverized fuel

include

· Complete combustion

· Simpler ash disposal

· Absence of smoke

· Use of cheap fuel

· Equipment adaptable to other fuels (oil and

gas)

· Easy control of air & fuel supply

· Absence of all moving parts in the furnace

· No stand by losses

· Lower labor cost

· Increase of capacity per unit furnace volume

· Higher efficiency

Grate

and Stokers:-

Grate:- a sectional metallic structure

designed to support the fuel in a furnace and to permit passage of primary

combustion air through openings to the fuel.

Stoker:- it is a power-operated fuel

feeding mechanism. It is used for supplying solid fuel to a furnace and

admitting air to the fuel for proper combustion.

By the use of stokers;

· A cheaper grade of fuel can be burned with

higher efficiency.

· Greater operational efficiency.

· Better maintenance of the furnace.

· Production of less smoke.

Stokers can be;

ü Travelling grate

ü Overfeed stokers

ü Spreader

ü Underfeed stokers

(1). Boiler feed pump:-

A high capacity induction motor is used to

feed the water to the boiler. The boiler feed pump is the highest power-consuming

auxiliaries in the steam power plants.

Feedwater:- natural water cannot be

used as such for steam generation as it contains solid, liquid and gaseous

impurities, which damage the blades of the turbine.

(2). Air preheater:-

Air preheaters are used to extract heat

from the flue gases to the combustion air. The advantages of preheaters are;

· Improved combustion

· Successful burning of low-grade fuel

· Increased efficiency and increased capacity

of plant

Air preheaters apply

either convection or the regeneration principle of heat transmission.

(3). Draught system:-

· To supply air to the furnace and to the

furnace and to take the flue gases from the boiler through the chimney.

· The pressure difference known as the draft is

usually measured in centimeters (cm) of water gauge.

· The resistance to the flow air and flue

gases which make the draught system necessary are;

o Ducts, stacks, chimney, fuel beds, dampers,

air preheaters, economizers, accumulation of sooth and ashes in gas passages

etc.

o Natural draught: if the pressure difference

is by chimney or stack.

o Forced draught: fans are used to create

pressure difference.

o Two types of fans; forced draught(FD) and

induced draught(ID) fans.

(4). Economizers:-

· Used to extract heat from the flue gases for

the heating of feed water.

· They may be placed in the last flue gas pass

within the boiler setting or in the casing between the boiler setting and the

chimney or stack.

· Economizers increase the resistance to the

flow of flue gases and also reduces their temperature and therefore induced

draft is required.

(5). Superheaters and Reheaters:-

The steam that exists at the

vaporization temperature corresponding to its absolute pressure is defined as

saturated steam, which may or may not carry water with it.

The temperature and total enthalpy of the saturated steam, at any pressure can be increased by the application of additional heat. i.e, superheating.

The temperature and total enthalpy of the saturated steam, at any pressure can be increased by the application of additional heat. i.e, superheating.

Advantages of superheating of steam are;

· The additional heat imparted to vapor

causes it to behave more likely to perfect gas.

· Steam condensation can be avoided.

· Increases efficiency.

· Elimination of moisture.

Superheaters are

simple heat exchangers for imparting additional energy to steam for a given

pressure.

A reheater is essentially a superheater, as it is designed to bring the partially expanded steam back to

superheat temperature by passing it through the tubes.

(6). Turbines:-

Turbine,

used to rotate the synchronous alternator is a device that converts steam

energy to rotational K.E. can be classified on the basis of steam flow

direction, expansion process, no. Of stages, speed etc.

The P.E in steam due to pressure and

internal energy is converted to K.E when passing through the nozzles.

In impulsive turbines, the steam expands in the stationary nozzles and attains higher velocity.

There are several stationary blades and moving blades. In reaction turbines, there are no nozzles, but they have also fixed and moving blades.

In impulsive turbines, the steam expands in the stationary nozzles and attains higher velocity.

There are several stationary blades and moving blades. In reaction turbines, there are no nozzles, but they have also fixed and moving blades.

· The rating of the generating unit depends on the

rating of turbines.

· Commercial turbines use a series combination

of impulse and reaction turbines.

· To increase the shaft output, several stages

are used (HP, IP, and LP turbines). For a lower rating of alternator only one

stage is used.

Classification of turbines

Basis of classification

a) Expansion process:-

o Impulse

turbine

o Reaction turbine

o Combination of impulse and reaction turbine

b) Steam flow direction

o Axial turbine

o Radial turbine

o Tangential turbine

c) No. Of stages

o Single-stage turbine

o Multi-stage turbine

§ Velocity compounded impulse (Curtis stage)

§ Pressure compounded impulse (Rateau stage)

§ Pressure-velocity compounded impulse (

Curtis-Rateau stage)

§ Pressure compounded reaction turbine

(parson’s stage)

d) No. Of flows

o Single flow

o Double flow

o Divided flow

o Tandem or cross compounded

e) The relative motion of rotor

o Single rotation

o Double rotation

f) Rotational speed

o N= 3000 rpm, f = 50 Hz

o N= 3600 rpm, f = 60 Hz

o N= 1500 rpm, f = 50 Hz

o Geared units

g) Applications

o Electric power generation

o Industrial

o Marine

h) Steam conditions

o High-pressure non-condensing

o High pressure condensing

o Backpressure

o Regenerative

o Reheating

o Extraction

o Mixed pressure

o Exhaust pressure turbine

(7). Condenser:-

§ It

is a device in which the exhaust steam from engines and turbines is condensed

and air and other non-condensable gases are removed in a continuous process.

Advantages are;

o To increase the efficiency of plant

o Recovery of condensate for re-use as boiler

water

· Two types;

o Surface

o Jet

· Cooling of the surface of condenser is

required.

(8). Cooling tower:-

§ Forms

the major section of the condensing system.

§ In closed cooling system, involving the

cooling towers, the cooling tower follows a closed cycle through the cooling

tower.

§ Types are

o Natural type

o Mechanical draught type

(9). Alternators:-

§ High

speed synchronous generators are used because the efficiency of steam turbines

is high at high speed.

§ If ‘P’ is the no. of poles and f is

the frequency of the system, the speed (N) in revolution per minute (rpm) is

given by,

§ Highest possible speed for 50 Hz supply

system is 3000 rpm [P=2].

§ For 60 Hz, it is 3600 rpm.

§ Field winding is placed at the rotor and

armature winding at the stator.

Concentric type:-

o Straight

bars are placed in series enclosed slots and separate end connectors are

concentrically disposed.

o The yoke is extended at either end to protect

the end windings.

o Core conductors are placed in semi-enclosed

slots ( internal reactance of the machine is high)

o There may be 3 or more coils per slot with

graded insulation.

o Concentric windings are preferred in high

voltage machine.

The maximum rating of the alternators are

21KV, 500 MW. Other ratings are 11KV, 50MW; 11KV,100/110MW; 15.56 KV, 200/210

MW.

Cooling of Alternators

o Required due to damage of insulation at high

temperatures.

o Open circuit cooling ( air is drawn by fans

and discharged to the atmosphere).

o Closed-circuit ( fixed volume of H2

is recirculated) is widely used.

General layout of Steam Power Station|Steam Power plant Lay out

Reviewed by Sikha

on

July 03, 2013

Rating:

Reviewed by Sikha

on

July 03, 2013

Rating:

Reviewed by Sikha

on

July 03, 2013

Rating:

Reviewed by Sikha

on

July 03, 2013

Rating:

No comments:

Post a Comment